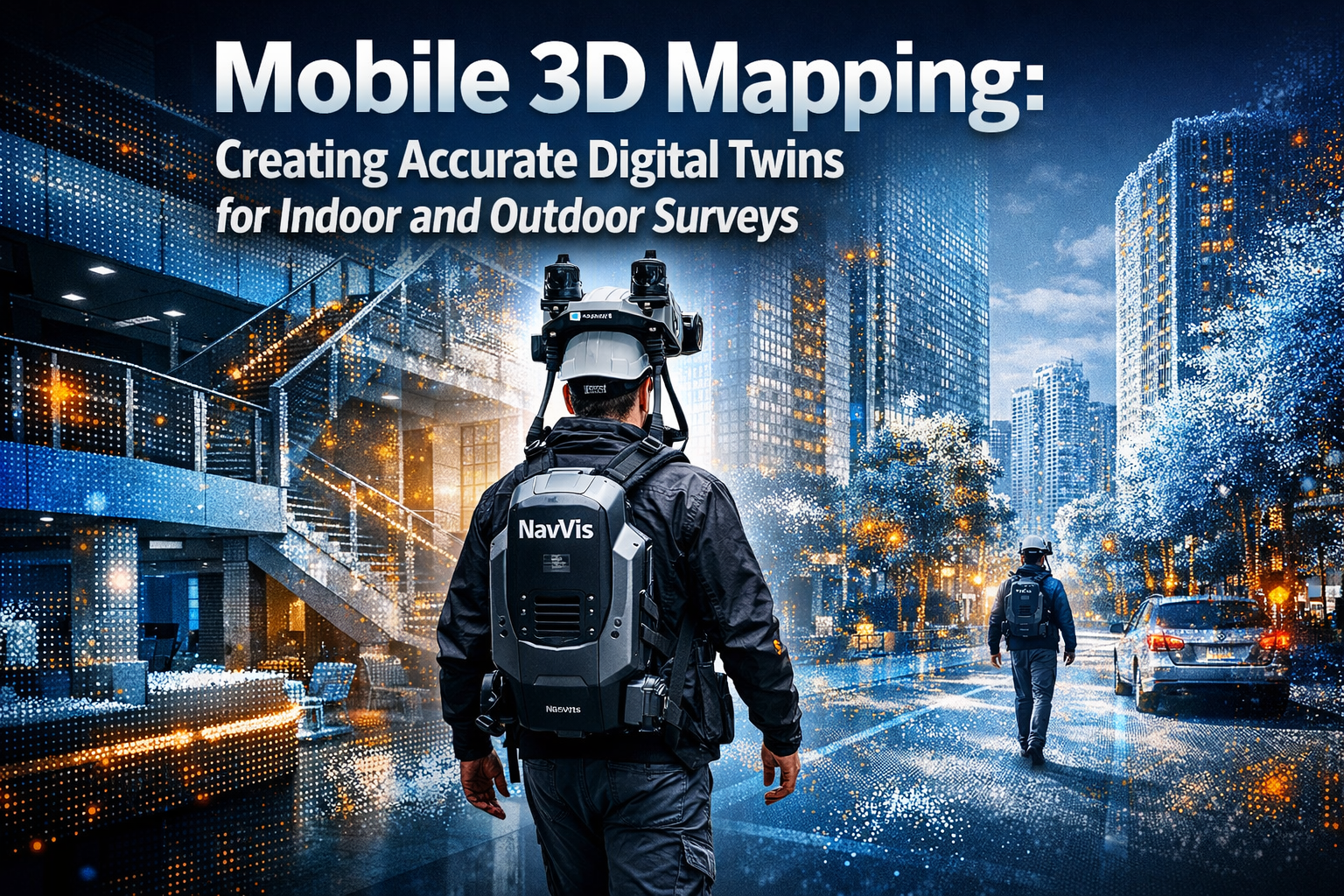

Imagine capturing an entire city block—complete with buildings, streets, and infrastructure—in just hours instead of weeks. In 2026, mobile 3D mapping technology is revolutionizing how professionals create digital twins, transforming bulky, stationary survey equipment into flexible, wearable systems that generate centimeter-accurate models while walking through spaces. This breakthrough enables chartered surveyors, urban planners, and facility managers to document complex environments without disrupting daily operations, delivering actionable spatial intelligence faster than ever before.

Mobile 3D mapping combines lightweight sensors, advanced cameras, and real-time processing to create accurate digital twins—virtual replicas of physical spaces that serve as living databases for asset management, planning, and analysis. Unlike traditional surveying methods requiring tripod-mounted equipment and repeated site visits, these portable systems capture both indoor and outdoor environments seamlessly, integrating data into Building Information Modeling (BIM) and Geographic Information Systems (GIS) workflows that drive operational decisions.

Key Takeaways

- Mobile mapping systems integrate wearable, handheld, and robotic platforms to capture survey-grade 3D data without disrupting operations, reducing field time by up to 70% compared to traditional methods

- Digital twins created from mobile mapping enable remote safety audits with sub-centimeter accuracy, virtual scenario testing, and asset management across facility and city scales

- Advanced camera technology including high-resolution sensors and HDR capabilities prevents data loss in challenging lighting conditions, capturing micro-cracks and surface details critical for infrastructure monitoring

- End-to-end workflows now connect LiDAR point clouds directly to operational platforms like ArcGIS Indoors, structuring facility intelligence around assets, work orders, and space utilization

- Real-world deployments demonstrate scalability from single buildings to entire housing developments, with projects capturing over 40,000 aerial photographs to create browser-based digital twins of 1,750+ homes

Understanding Mobile 3D Mapping Technology

Mobile 3D mapping represents a fundamental shift from stationary surveying to continuous data capture while in motion. These systems combine multiple sensors—including LiDAR (Light Detection and Ranging), high-resolution cameras, inertial measurement units (IMUs), and GNSS (Global Navigation Satellite System) receivers—into portable packages that professionals can wear, carry, or mount on vehicles and robots.

Core Components of Mobile Mapping Systems

Modern mobile mapping platforms integrate several critical technologies working in synchronized harmony:

LiDAR Sensors emit millions of laser pulses per second, measuring the time each pulse takes to return after bouncing off surfaces. This generates dense point clouds—collections of millions of precisely positioned 3D coordinates that represent physical geometry. Survey-grade mobile LiDAR achieves accuracy within 1-3 centimeters, sufficient for detailed infrastructure documentation and boundary surveys.

High-Resolution Cameras capture detailed imagery that adds color and texture information to point clouds while enabling photogrammetry—the science of making measurements from photographs. Dense image datasets reduce interpolation errors and enable detection of micro-cracks, surface wear, or subtle geometric shifts in infrastructure, improving digital twin realism and reliability for asset management[1].

Inertial Measurement Units (IMUs) track the system's position, orientation, and movement in three-dimensional space. These sensors measure acceleration and rotation hundreds of times per second, allowing software to determine exactly where the scanner was positioned when each data point was captured—even when GPS signals are unavailable indoors.

GNSS Receivers provide global positioning when operating outdoors, anchoring the collected data to real-world coordinates. Advanced systems use Real-Time Kinematic (RTK) corrections to achieve centimeter-level positioning accuracy, ensuring digital twins align precisely with existing survey control networks.

Platform Types and Applications

Mobile 3D mapping technology manifests in several form factors, each optimized for specific environments and use cases:

| Platform Type | Best Use Cases | Key Advantages | Typical Accuracy |

|---|---|---|---|

| Wearable Systems (e.g., NavVis VLX3) | Large indoor facilities, continuous mapping | Hands-free operation, rapid coverage | 1-3 cm |

| Handheld Scanners (e.g., BLK2GO) | Detailed environment capture, complex spaces | Portability, ease of use | 1-2 cm |

| Vehicle-Mounted | Roads, urban corridors, large outdoor areas | High-speed capture, extensive range | 2-5 cm |

| Robotic Platforms | Hazardous areas, confined spaces, tunnels | Access restricted zones, autonomous operation | 1-3 cm |

The Scan2Twin methodology, publicly demonstrated for the first time at Geo Week 2026 on February 16, 2026, at the Colorado Convention Center in Denver, integrates three reality capture methods: NavVis VLX3 wearable systems for continuous mobile mapping, BLK2GO handheld scanners for detailed environment capture, and robotic quadrupeds for accessing restricted or low-clearance spaces—enabling survey-grade data collection without disrupting operations[2].

Mobile 3D Mapping: Creating Accurate Digital Twins for Indoor and Outdoor Surveys in Practice

The transformation from raw sensor data to actionable digital twins requires sophisticated processing workflows that convert billions of measurements into structured, queryable information. Understanding this pipeline reveals how mobile mapping delivers value across diverse applications.

From Point Clouds to Intelligent Models

Data Acquisition begins with planning the survey route to ensure complete coverage without gaps. Operators wearing or carrying mobile mapping systems walk through spaces at normal pace—typically 1-2 meters per second—while sensors continuously capture data. A single operator can document 5,000-10,000 square meters per hour, dramatically outpacing traditional survey methods[1].

Processing and Registration involves aligning all captured data into a unified coordinate system. Sophisticated algorithms analyze overlapping scans, matching common features to "stitch" individual scans into seamless models. The Scan2Twin pipeline controls this full data journey from LiDAR point clouds through BIM processing to operational ArcGIS Indoors deployment, delivering facility intelligence structured around assets, work orders, and space use rather than visualization alone[2].

Classification and Extraction applies artificial intelligence to identify specific objects within point clouds. Machine learning algorithms trained on millions of examples can automatically recognize walls, doors, windows, mechanical equipment, and infrastructure elements. This semantic enrichment transforms simple geometric data into intelligent digital twins that understand what each element represents.

Integration with Existing Systems connects digital twins to enterprise platforms where facility managers and planners work daily. Modern workflows export directly to Autodesk Revit for BIM coordination, Esri ArcGIS for spatial analysis, or specialized facility management software—ensuring spatial intelligence flows into operational decision-making.

Overcoming Technical Challenges

Mobile mapping systems must address several technical hurdles to maintain accuracy and reliability:

Dynamic Lighting Management poses significant challenges as systems transition between bright outdoor environments and dimly lit interiors. High Dynamic Range (HDR) cameras simultaneously record details across highlights and shadows, preventing structural information loss in mapping systems that encounter lighting extremes—from bright outdoor reflective surfaces to shaded interiors or tunnels[1].

Multi-Camera Synchronization ensures each frame across all cameras is captured at identical instants, preventing temporal drift and frame mismatches when data is combined with LiDAR or GNSS inputs, maintaining reliable depth and spatial accuracy[1]. This synchronization operates at millisecond precision, coordinating multiple data streams into coherent datasets.

Real-Time Processing Power has become achievable through integration with NVIDIA Jetson Orin NX and AGX Orin platforms, which support GPU-accelerated pipelines for handling high-resolution feeds, HDR data, and multi-camera inputs simultaneously, with neural networks for object detection enabling semantic information incorporation[1]. These embedded computing platforms process data on-site, providing immediate quality feedback to operators.

GNSS-Denied Environments require alternative positioning strategies when mapping indoors or in urban canyons where satellite signals are blocked. Advanced systems employ Simultaneous Localization and Mapping (SLAM) algorithms that track position by analyzing how the environment changes as the sensor moves, creating accurate maps without external positioning references.

Real-World Applications and Case Studies 🏗️

Mobile 3D mapping technology proves its value through tangible results in infrastructure projects, urban development, and facility management. These applications demonstrate how accurate digital twins drive better decisions and measurable cost savings.

Urban Development and Housing Projects

The Northstowe housing development in the UK showcases mobile mapping at unprecedented scale. This project captured over 40,000 high-resolution aerial photographs to create a true-to-scale 3D digital model, with 1,750 homes visible and measurable in the browser-based digital twin as of summer 2025[4].

This comprehensive digital twin enables:

- Planning coordination across multiple contractors working simultaneously

- Progress monitoring comparing as-built conditions against design intent

- Public engagement allowing future residents to visualize the community before construction completes

- Infrastructure planning for utilities, roads, and community facilities with precise spatial context

The same mobile mapping system can handle both indoor and outdoor environments seamlessly, with the ability to document a single facility using the same workflow as an entire city district, allowing new data integration without disrupting previously captured information[1]. This scalability proves essential for projects spanning multiple phases over several years.

Transportation Infrastructure Analysis

Digital twins enable remote safety audits with sub-centimeter accuracy, revealing hazards like poor sightlines or hazardous curves without field visits, and allow planners to test "what-if" scenarios virtually—such as adding turn lanes or changing signal timing—before committing resources[3].

Transportation agencies leverage mobile mapping for:

✅ Highway corridor documentation capturing road geometry, signage, pavement conditions, and drainage infrastructure in single passes at highway speeds

✅ Intersection analysis measuring sight distances, clearance zones, and pedestrian facilities to identify safety improvements

✅ Bridge inspection documenting structural elements, measuring clearances, and tracking deterioration over time through comparative analysis

✅ Rail corridor surveys mapping tracks, catenary systems, platforms, and adjacent structures while minimizing disruption to operations

Mobile mapping captures complex environments quickly, reducing hours spent in the field and lowering costs by eliminating the need for repeated site visits, while maintaining high coverage and consistency compared to static survey methods[1]. Projects that previously required weeks of field work now complete in days, with more comprehensive data coverage.

Facility Management and Operations

The operational deployment capabilities demonstrated in the Scan2Twin showcase include practical facilities team capabilities including turn-by-turn indoor routing to assets, work order visualization in spatial context, and space management and planning tools[2].

Facility managers apply digital twins created through mobile mapping to:

Asset Management – Every piece of equipment, from HVAC units to fire extinguishers, receives precise 3D coordinates. Maintenance technicians navigate directly to assets using indoor positioning, while managers track equipment lifecycles and plan replacements based on spatial relationships and access requirements.

Space Utilization Analysis – Digital twins reveal how spaces are actually used versus designed intent. Organizations identify underutilized areas, optimize layouts, and plan renovations with confidence, supported by accurate measurements extracted directly from point cloud data.

Emergency Response Planning – First responders access detailed building models showing room layouts, exit routes, hazardous material locations, and utility shutoffs. This spatial intelligence proves critical during incidents when every second matters.

Renovation and Retrofit Design – Architects and engineers work from accurate as-built conditions rather than outdated drawings. Schedule of condition reports document existing conditions before construction begins, protecting all parties from disputes about pre-existing damage.

Commercial Property Applications

Commercial property surveyors increasingly rely on mobile 3D mapping for comprehensive building documentation. The technology supports:

- Dilapidation surveys providing irrefutable evidence of property conditions through precise measurements and photorealistic documentation

- Lease negotiations where accurate floor area calculations and space configurations inform rental valuations

- Building compliance verification against accessibility standards, fire codes, and planning permissions

- Property marketing with immersive 3D tours and accurate floor plans generated from survey data

When combined with drone roof surveys, mobile indoor mapping creates complete building envelopes—exterior and interior—in unified digital models that support comprehensive property analysis.

Technical Specifications and Accuracy Standards 📊

Understanding the technical capabilities and limitations of mobile 3D mapping systems helps professionals select appropriate tools and set realistic expectations for project deliverables.

Accuracy Metrics and Validation

Mobile mapping accuracy depends on multiple factors working together:

Absolute Accuracy measures how closely digital twin coordinates match real-world positions established by survey control networks. High-end mobile systems achieve 1-3 cm absolute accuracy when properly calibrated and operated with GNSS corrections or survey control targets.

Relative Accuracy describes how precisely points relate to each other within the dataset, regardless of absolute position. Mobile systems typically achieve sub-centimeter relative accuracy, meaning measurements between features within the model (distances, angles, areas) are extremely reliable even if the entire model shifts slightly in global coordinates.

Range and Resolution determine the level of detail captured. Most mobile LiDAR systems effectively scan objects 0.5-30 meters away, with point spacing of 5-10 millimeters at typical operating distances. This resolution captures architectural details, mechanical equipment, and infrastructure features with sufficient detail for most applications.

Validation Methods ensure quality through:

- Check measurements comparing known distances to model measurements

- Target spheres placed at surveyed locations to verify absolute positioning

- Overlap analysis examining consistency where scan areas overlap

- Comparison to control surveys using total station measurements as ground truth

Data Output Formats and Standards

Mobile mapping systems generate multiple data products serving different purposes:

| Output Format | Primary Use | Typical File Size | Industry Standards |

|---|---|---|---|

| Point Clouds (.las, .laz) | Detailed measurements, analysis | 1-10 GB per 10,000 m² | ASPRS LAS specification |

| Mesh Models (.obj, .fbx) | Visualization, VR/AR applications | 100 MB – 2 GB | Industry standard 3D formats |

| BIM Models (.rvt, .ifc) | Design coordination, construction | 50-500 MB | IFC, COBie standards |

| CAD Drawings (.dwg, .dxf) | 2D plans, elevations, sections | 10-50 MB | AutoCAD standards |

| Panoramic Images (.jpg, .tif) | Visual documentation, measurements | 20-50 MB per panorama | Standard image formats |

| GIS Datasets (geodatabase) | Spatial analysis, asset management | 100 MB – 5 GB | OGC, Esri standards |

Professional workflows increasingly demand interoperability—the ability to exchange data seamlessly between platforms. Modern mobile mapping systems support Industry Foundation Classes (IFC) for BIM, LAS/LAZ for point clouds, and geodatabase formats for GIS, ensuring digital twins integrate into existing technology ecosystems.

Processing Requirements and Timelines

Converting raw mobile mapping data into finished digital twins requires significant computational resources:

Processing Time typically runs 1-3 hours of computation per hour of field collection, depending on data density and desired outputs. Cloud-based processing services now offer distributed computing that accelerates delivery, with some providers returning initial results within hours of upload.

Storage Requirements scale with project size. A comprehensive building survey generating 50 GB of raw data might compress to 10-15 GB for long-term archival, while derivative products (BIM models, drawings, visualizations) add another 5-10 GB.

Quality Control represents 20-30% of total project time, as technicians verify accuracy, remove artifacts, classify objects, and extract features. Automated workflows reduce this burden, but human review remains essential for critical applications.

Integration with Building Information Modeling and GIS 🔗

The true power of mobile 3D mapping emerges when digital twins connect to enterprise systems that drive operational decisions. Modern workflows bridge the traditional divide between design (BIM) and operations (GIS).

BIM Integration Workflows

Scan-to-BIM processes transform point clouds into parametric building models containing intelligent objects rather than simple geometry. This workflow supports:

Renovation Design – Architects overlay proposed designs onto accurate existing conditions, identifying conflicts before construction begins. Structural engineers verify load paths and connection points against as-built framing rather than assumptions.

MEP Coordination – Mechanical, electrical, and plumbing systems require precise spatial coordination. Mobile mapping reveals actual pipe runs, duct routing, and equipment locations, enabling clash detection between existing systems and proposed modifications.

Construction Verification – Contractors compare as-built conditions against design intent, documenting deviations and generating redline drawings that update project records. This quality assurance prevents costly rework and ensures facility management receives accurate information.

Heritage Preservation – Historic buildings often lack accurate documentation. Mobile mapping captures intricate architectural details, ornamental features, and structural systems, creating digital archives that inform conservation work and disaster recovery.

GIS and Facility Management Platforms

The end-to-end workflow integration demonstrated by Scan2Twin connects LiDAR point clouds directly to operational ArcGIS Indoors deployment, delivering facility intelligence structured around assets, work orders, and space use[2]. This operational focus transforms digital twins from visualization tools into decision-support systems.

Indoor Positioning and Navigation leverages digital twins to provide turn-by-turn directions inside buildings where GPS signals fail. Employees locate meeting rooms, visitors find departments, and maintenance technicians navigate to equipment using mobile apps connected to spatial databases.

Space Management analyzes how organizations use their facilities. Digital twins integrated with occupancy sensors, badge readers, and scheduling systems reveal utilization patterns, informing decisions about workspace allocation, hoteling programs, and real estate optimization.

Asset Lifecycle Management tracks equipment from installation through decommissioning. Each asset's 3D position connects to maintenance histories, warranty information, and replacement schedules, enabling predictive maintenance and capital planning based on spatial relationships.

Emergency Management provides first responders with detailed building intelligence. Digital twins show room layouts, exit paths, assembly points, and hazardous material locations, while real-time sensor integration adds fire alarm status, access control states, and environmental conditions.

Cloud Platforms and Collaborative Workflows

Modern digital twin platforms operate in cloud environments that enable global collaboration:

- Browser-based access eliminates software installation requirements, allowing stakeholders to view and query models from any device

- Version control tracks changes over time, documenting facility evolution and supporting historical analysis

- Role-based permissions ensure appropriate access levels for different user groups

- API connectivity allows custom applications to query spatial data and integrate with enterprise systems

The Northstowe project's browser-based digital twin exemplifies this approach, making 1,750 homes accessible to planners, contractors, and stakeholders without specialized software[4].

Cost-Benefit Analysis and Return on Investment 💰

Organizations considering mobile 3D mapping investments must evaluate costs against tangible benefits. Real-world data demonstrates compelling returns across multiple dimensions.

Direct Cost Savings

Reduced Field Time represents the most immediate benefit. Mobile mapping captures complex environments quickly, reducing hours spent in the field and lowering costs by eliminating the need for repeated site visits[1]. Projects report:

- 50-70% reduction in survey time compared to traditional total station methods

- Single-visit data collection versus multiple trips for different disciplines

- Elimination of traffic control costs for roadway surveys through rapid capture

- Reduced insurance and safety costs from shorter exposure to hazardous environments

Labor Efficiency multiplies when one mobile mapping operator replaces multiple traditional survey crews. A single technician with wearable scanning equipment can document facilities that previously required teams of surveyors working for weeks.

Rework Prevention through accurate as-built documentation prevents costly design errors. Engineering firms report that digital twins reduce RFIs (Requests for Information) during construction by 30-40% and minimize change orders stemming from unexpected field conditions.

Operational Benefits

Faster Decision Making accelerates project timelines when stakeholders access comprehensive spatial data immediately. Virtual site visits replace physical travel, enabling remote experts to contribute without delays.

Improved Collaboration emerges when all disciplines work from identical, accurate base information. Architects, engineers, contractors, and facility managers reference the same digital twin, eliminating discrepancies between different survey datasets.

Risk Mitigation through comprehensive documentation protects organizations legally and operationally. Dilapidation surveys conducted with mobile mapping provide irrefutable evidence of pre-existing conditions, while detailed as-builts support warranty claims and dispute resolution.

Asset Optimization extends equipment lifecycles and reduces maintenance costs. Organizations report 15-25% reductions in reactive maintenance when digital twins enable predictive strategies based on accurate condition assessment and spatial analysis.

Strategic Value Creation

Beyond direct savings, mobile 3D mapping enables new capabilities:

Portfolio Management across multiple properties becomes feasible when standardized digital twins provide consistent data. Real estate organizations compare facility conditions, benchmark performance, and prioritize capital investments based on comprehensive spatial intelligence.

Sustainability Analysis leverages digital twins for energy modeling, daylighting studies, and carbon footprint calculations. Accurate building geometry feeds simulation tools that optimize environmental performance.

Innovation Enablement as digital twins serve as platforms for emerging technologies. Organizations layer IoT sensor data, integrate augmented reality applications, and deploy autonomous robots using spatial frameworks established through mobile mapping.

Future Trends and Emerging Technologies 🚀

Mobile 3D mapping continues evolving rapidly, with several technological advances poised to expand capabilities and applications in coming years.

Artificial Intelligence and Automation

Automated Feature Extraction increasingly applies deep learning to recognize and classify objects within point clouds. Neural networks trained on millions of examples automatically identify:

- Building elements (walls, doors, windows, stairs)

- Infrastructure components (pipes, ducts, conduits, equipment)

- Defects and damage (cracks, corrosion, deformation)

- Vegetation and terrain features in outdoor environments

This automation reduces processing time from days to hours while improving consistency and enabling analysis at scales previously impractical.

Semantic Segmentation assigns meaning to every point in the cloud, creating intelligent models that understand context. Advanced systems distinguish between load-bearing walls and partitions, identify equipment by manufacturer and model, and recognize hazardous conditions requiring attention.

Predictive Maintenance combines digital twins with historical data to forecast equipment failures. Machine learning algorithms analyze spatial patterns, usage intensity, and environmental conditions to recommend interventions before breakdowns occur.

Sensor Fusion and Multi-Modal Capture

Next-generation systems integrate additional sensor types for richer environmental understanding:

Thermal Imaging detects temperature variations indicating energy loss, moisture intrusion, or equipment malfunctions. Combined with geometric data, thermal information creates comprehensive building performance assessments.

Ground Penetrating Radar reveals subsurface features—utilities, foundations, voids—that complement above-ground mapping. This integration proves essential for infrastructure projects requiring complete spatial understanding.

Acoustic Sensors capture sound characteristics for noise mapping and vibration analysis, supporting industrial facility optimization and environmental compliance.

Chemical Sensors detect gas concentrations, air quality parameters, and environmental contaminants, enabling digital twins that monitor health and safety conditions in real-time.

Real-Time Digital Twins and IoT Integration

Static digital twins are evolving into dynamic systems that update continuously:

Sensor Networks embedded throughout facilities stream real-time data into digital twin platforms. Temperature, occupancy, equipment status, and environmental conditions overlay spatial models, enabling immediate response to changing conditions.

Autonomous Systems navigate using digital twins as reference maps. Robotic platforms perform routine inspections, inventory management, and cleaning operations guided by precise spatial intelligence.

Augmented Reality Applications overlay digital information onto physical environments through mobile devices and headsets. Maintenance technicians see equipment manuals, work instructions, and diagnostic data superimposed on actual machinery, while designers visualize proposed changes in context.

Democratization and Accessibility

Technology trends point toward broader adoption:

Lower Cost Systems bring mobile mapping capabilities to smaller organizations. Consumer-grade devices now achieve accuracies sufficient for many applications at fraction of professional system costs.

Simplified Workflows reduce technical barriers through automated processing and intuitive interfaces. Cloud platforms handle computational complexity, delivering finished digital twins without specialized expertise.

Mobile Device Integration leverages smartphones and tablets as capable mapping tools. Advanced devices with LiDAR sensors enable quick facility documentation and measurements without dedicated equipment.

Best Practices for Implementing Mobile 3D Mapping Programs 📋

Organizations seeking to adopt mobile 3D mapping benefit from structured approaches that maximize value while managing risks and costs.

Planning and Scoping

Define Clear Objectives before selecting technology or vendors. Understand specific use cases, required accuracy levels, and intended workflows. Different applications demand different capabilities—facility management requires different outputs than structural engineering.

Assess Current Capabilities to identify gaps and opportunities. Organizations with existing BIM or GIS platforms should prioritize solutions offering seamless integration. Those starting fresh might benefit from comprehensive platforms handling the entire workflow.

Pilot Projects reduce risk by testing technology on limited scope before enterprise deployment. Select representative facilities or projects that demonstrate value while allowing learning without critical consequences.

Stakeholder Engagement ensures adoption across disciplines. Involve facility managers, engineers, designers, and operations teams early to understand requirements and build support for new workflows.

Technology Selection Criteria

Evaluate mobile mapping systems across multiple dimensions:

✅ Accuracy Requirements – Match system capabilities to project needs; not all applications require millimeter precision

✅ Environment Compatibility – Consider indoor/outdoor requirements, lighting conditions, and accessibility constraints

✅ Data Processing – Evaluate whether in-house processing is feasible or cloud services are preferred

✅ Integration Capabilities – Verify compatibility with existing software platforms and data standards

✅ Training and Support – Assess vendor support quality, training programs, and user community resources

✅ Total Cost of Ownership – Include equipment, software licenses, processing services, training, and maintenance in financial analysis

Quality Assurance Protocols

Establish procedures ensuring consistent, reliable results:

Pre-Survey Planning includes route design for complete coverage, identification of control points, and coordination with facility operations to minimize disruptions.

Field Procedures standardize data collection techniques, equipment calibration, and documentation practices. Operators should verify data quality on-site before leaving locations.

Processing Standards define acceptable accuracy thresholds, classification schemes, and output specifications. Documented workflows ensure consistency across projects and technicians.

Validation and Verification through independent checks confirm digital twins meet requirements. Compare model measurements against known dimensions, verify control point accuracy, and assess completeness.

Training and Skill Development

Successful programs invest in people:

- Operator Training covering equipment operation, data collection best practices, and field quality control

- Processing Skills for technicians handling point cloud registration, classification, and feature extraction

- Application Training helping end-users leverage digital twins effectively in their workflows

- Continuous Learning as technology evolves rapidly, requiring ongoing skill updates

Conclusion

Mobile 3D mapping has fundamentally transformed how professionals create accurate digital twins for indoor and outdoor surveys in 2026. By replacing bulky, stationary equipment with flexible wearable, handheld, and robotic systems, this technology delivers survey-grade accuracy while dramatically reducing field time and operational disruption. From comprehensive housing developments capturing 40,000+ aerial photographs to detailed facility documentation enabling turn-by-turn indoor navigation, real-world applications demonstrate tangible value across infrastructure, urban planning, and facility management domains.

The integration of advanced sensors—including high-resolution HDR cameras, synchronized multi-camera arrays, and GPU-accelerated processing platforms—ensures reliable data capture across challenging lighting conditions and complex environments. End-to-end workflows connecting LiDAR point clouds to operational BIM and GIS platforms transform raw measurements into actionable intelligence structured around assets, work orders, and space utilization rather than visualization alone.

Organizations implementing mobile 3D mapping programs report 50-70% reductions in survey time, significant decreases in design conflicts and rework, and new capabilities for predictive maintenance and portfolio management. As artificial intelligence automates feature extraction, sensor fusion enriches environmental understanding, and cloud platforms democratize access, digital twins will increasingly serve as living operational platforms rather than static documentation.

Next Steps for Implementation

For Organizations Considering Mobile Mapping:

- Identify pilot projects with clear ROI potential—facility renovations, infrastructure assessments, or property documentation where traditional methods prove time-consuming or costly

- Engage qualified professionals including chartered surveyors experienced in mobile mapping workflows and digital twin creation

- Evaluate integration requirements with existing BIM, GIS, or facility management platforms to ensure seamless data flow

- Establish quality standards defining acceptable accuracy, completeness, and deliverable specifications for your applications

- Plan for ongoing value extraction by connecting digital twins to operational systems rather than treating them as one-time deliverables

For Professionals Expanding Capabilities:

- Attend industry showcases like Geo Week 2026 to experience emerging technologies firsthand

- Pursue training in point cloud processing, BIM integration, and GIS workflows

- Develop expertise in specific application domains—transportation, facilities, heritage preservation—where specialized knowledge creates competitive advantage

- Build partnerships between survey, design, and technology providers to deliver comprehensive solutions

The convergence of mobile 3D mapping, digital twins, and operational intelligence platforms represents more than technological advancement—it fundamentally reimagines how built environments are documented, understood, and managed throughout their lifecycles. Organizations embracing these capabilities position themselves to make faster, better-informed decisions supported by comprehensive spatial intelligence that evolves alongside the facilities and infrastructure they steward.

References

[1] 3d Mobile Mapping For Digital Twins – https://www.electronicspecifier.com/studentzone/learning/year-2/digital-systems-and-design/3d-mobile-mapping-for-digital-twins/

[2] Geoconvergence Introduces Scan2twin Mobile Mapping For Digital Twin Creation Gis Integration – https://www.geoweeknews.com/news/geoconvergence-introduces-scan2twin-mobile-mapping-for-digital-twin-creation-gis-integration

[3] Mapping The Future Of Digital Twins Transforming Transportation Cad To Gis – https://sanborn.com/blog/mapping-the-future-of-digital-twins-transforming-transportation-cad-to-gis/

[4] Mapping A New Town With 3d Digital Twin Technology – https://www.gim-international.com/content/news/mapping-a-new-town-with-3d-digital-twin-technology